<center id="coq2c"></center>

Application Overview

Spray drying is the most widely used process in liquid forming and drying industries. It is most suitable for generating powdery and granular products from solutions, emulsion, suspensions and pumpable paste liquid raw materials. Therefore, spray drying is a very ideal process when the particle size distribution, residual moisture content, bulk density and particle shape of the finished product must meet accurate standards.

Equipment characteristics

★ The drying speed is fast, and the surface area of the material liquid greatly increases after atomization. In the hot air flow, 95% -98% of the water can be instantly evaporated, and the drying time is only 5-40 seconds. It is particularly suitable for drying heat-sensitive materials.

★ The product has good dispersibility, flowability, or solubility. As the drying process is completed in air, it can basically maintain a spherical shape similar to the liquid droplet phase, with good dispersibility, flowability, and solubility, resulting in high purity and good quality of the product.

★ The production process is simplified and the operation and control are convenient. Usually used for solutions with a moisture content of 40-60% (up to 90% for special materials), they can be dried into powder products in one go. After drying, there is no need for crushing and screening, reducing production processes and improving product purity. The product particle size, bulk density, and moisture can be adjusted within a certain range by changing operating conditions, simplifying the production process and making control and management very convenient.

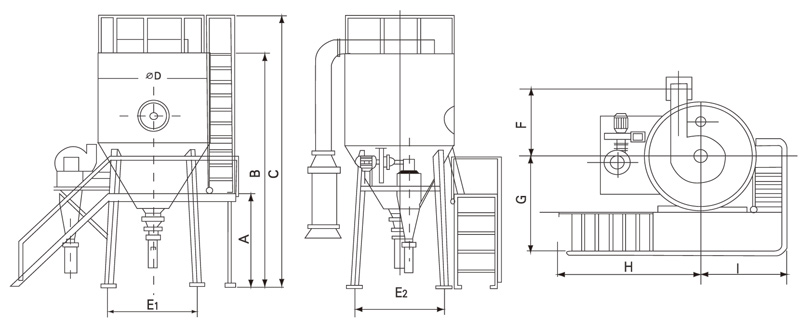

Installation reference diagram

Specification Items | 5 | 25 | 50 | 100 | 150 | 200-300 | |

Inlet temperature | ≤350℃ | ||||||

Outlet temperature | ≤80℃~90℃ | ||||||

Evaporation capacity(kg/h) | 5 | 25 | 50 | 100 | 150 | 200-300 | |

Transmission form | Compressed air drive | Mechanical drive | |||||

Speed (rpm) | 25000 | 22000 | 21500 | 18000 | 18000 | 15000 | |

Spray disc diameter (mm) | 50 | 120 | 120 | 120 | 150 | 180-340 | |

Heat source | Electricity | Electricity | Electricity+steam, fuel oil, coal vapor | Electricity+Steam | Electricity+steam, fuel oil, coal vapor | Resolved by the user themselves | |

Electric heating power (kW) | 9 | 45 | 60 | 81 | 99 | ||

Dry powder recovery rate (%) | ≥95 | ≥95 | ≥95 | ≥95 | ≥95 | ≥95 | |

Host size | A(mm) | 1000 | 1290 | 1730 | 2500 | 2800 | Determine based on actual situation |

B(mm) | 2100 | 3410 | 4245 | 5300 | 6000 | ||

C(mm) | 2300 | 4260 | 4645 | 6000 | 6700 | ||

?D(mm) | 1060 | 1800 | 2133 | 2560 | 2860 | ||

E1(mm) | 1050 | 1200 | 1640 | 2100 | 2180 | ||

E2(mm) | 1050 | 1200 | 1640 | 2100 | 2180 | ||

F(mm) | 750 | 1000 | 1250 | 1750 | 1970 | ||

G(mm) | 530 | 1700 | 1750 | 1930 | 2080 | ||

H(mm) | 530 | 1300 | 1800 | 2600 | 3050 | ||

l(mm) | 530 | 1550 | 1600 | 1780 | 1960 | ||

All parameters are for reference only, and our company has the right to make changes based on the material situation without prior notice.

<center id="coq2c"></center>