<center id="coq2c"></center>

Overview

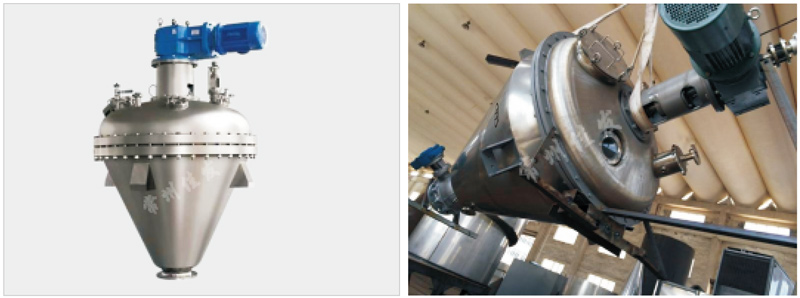

The conical spiral belt vacuum dryer is a type of material that uses spiral belts to rotate and lift materials, and the conical jacket and hollow spiral belt are simultaneously filled with heat transfer media (such as hot water, heat transfer oil, steam, etc.), so that the heated material is lifted from all around and falls from the middle, rapidly and continuously cycling and flipping, and the water vapor is promptly taken away through vacuum extraction inside the cylinder.

The conical spiral belt vacuum dryer is a multifunctional equipment that integrates mixing, drying, and distillation. It adopts a fully enclosed GMP cleaning design, and its drying efficiency is 3-5 times that of the same specification (double cone rotary vacuum dryer). The loading capacity can reach 80% of the cone volume, and the relative efficiency is increased by 6-10 times. The spiral belt stirrer can achieve a bottom-up spiral circulation stirring effect of materials, achieving efficient heat transfer characteristics. The material filling rate works at 30% -80%, and satisfactory utilization efficiency of heating area can be achieved. It is a new type of energy-saving, efficient, environmentally friendly and clean drying equipment.

Equipment characteristics

★ It can be equipped with flying knives and spray atomization assembly to meet special process requirements.

★ The discharge valve has two modes: manual and pneumatic.

★ Special materials can increase the power of the motor (heavy-duty).

Total Volume(L) | Working volume(L) | Heating area(m2) | Speed(r.p.m) | Power(KW) | Design pressure inside the tank(Mpa) | Design pressure of interlayer(Mpa) |

100 | 70 | 1.1 | 0-34 | 1.5 | -0.09~0.096 | 0.3 |

200 | 140 | 1.5 | 0-34 | 3 | ||

350 | 230 | 1.8 | 0-34 | 4 | ||

500 | 350 | 2 | 0-34 | 4 | ||

750 | 450 | 2. | 0-34 | 5.5 | ||

1000 | 700 | 3.8 | 0-34 | .5 | ||

1500 | 1100 | 4.6 | 0-30 | 11 | ||

2000 | 1400 | 6.3 | 0-26 | 15 | ||

3000 | 2100 | 7.5 | 0-20 | 18.5 | ||

4000 | 2800 | 9.1 | 0-18 | 30 | ||

5000 | 3500 | 12.2 | 0-15 | 45 |

All parameters are for reference only, and our company has the right to make changes based on the material situation without prior notice.

<center id="coq2c"></center>